Shinco Air Conditioner Error Codes: Inverter Split System Air Conditioner R410A

| Error Codes | Problem |

|---|---|

| E0 | Outdoor Discharge Pipe Sensor Fault |

| E1 | Indoor Air Sensor Is Faulty |

| E2 | Indoor Pipe Sensor Is Faulty |

| E3 | Indoor In-phase Motor Is Fault |

| E4 | Communication Fault Between Indoor Unit And Outdoor Unit |

| E5 | Driver Board Is Fault |

| E6 | Outdoor Sensor Is Fault |

| E7 | Indoor Motor Faulty |

| E8 | Communication Signal Is Not Good |

| E9 | Power Board Is Fault |

| EE | Indoor Pcb Baord Is Faulty |

| EC | Oudoor Communication Faulty |

| EA | Compressor Driver Board Is Faulty |

| EP | Indoor Unit Don’t Match Outdoor Unit |

| P0 | Driver Board Is Fault |

| P1 | OCR Triped |

| P2 | Power Board Is Fault |

| P3 | IPDU Is Fault |

| P4 | Indoor Unit Don’t Match Outdoor Unit |

| P5 | Electric Current Is Too High |

| P6 | The Voltage Is Not Stable |

| P7 | Pfc Faulty |

| P8 | Indoor Motor Feedback Faulty |

| FL | Water full status |

How to Fix?

Fault code display;

KFR-25GWZ/BM – KFR-35GWZ/BM Models;

Code: EP

Fault: Indoor Unit Don’t Match Outdoor Unit

Check Point: Check If The Indoor Unit Match Outdoor Uint

Count Measure: Change Wrong Unit

Code: E0

Fault: Outdoor Discharge Pipe Sensor Fault

Check Point:

- Checkthe Value Of Sensor

- Outdoor Power Board Is Fault(check capicator)

Count Measure:

- Change Sensor

- Change Power Board

Code: E4

Fault: Communication Fault Between Indoor Unit And Outdoor Unit

Check Point:

- Check if the connecting wiring is connect well

- Test the voltage value between L4 and S, if it ‘s change regularly, the singal transfering between indoor and outdoor unit is good, when it‘s no change if value is below 14v, the indoor pcb board is fault, change it. if value is over 14v, the outdoor pcb is faulty

- Check if there is led flashing on the outdoor pcb if there is no flashing, check voltage value from power board to pfc board, between acl and can on pfc board if it’s not 220v, change power board if it’s 220v, change pfc board

Count Measure:

- Fix The Wiring Again

- Change Relate Pcb Board

Code: EA

Fault: Compressor Driver Board Is Faulty

Check Point: Check Outdoor Driver Board

Count Measure: Change Driver Board

Code: E6

Fault:

- Ourdoor Air Sensor Is Faulty

- Outdoor Pipe Sensor Is Fault

Check Point:

- Check The Sendor Value

- Power Board Is Faul

Count Measure:

- Change Sensor

- Change Power Baord

Code: E1

Fault: Indoor Air Sensor Is Faulty

Check Point:

- Check The Sensor Value

- Indoor Board Is Fault

Count Measure:

- Change Sendor

- Change Indoor Board

Code: E2

Fault: Indoor Pipe Sensor Is Faulty

Check Point:

- Check The Sensor Value

- Indoor Board Is Fault

Count Measure:

- Change Sendor

- Change Indoor Board

Code: E8

Fault: Power Board Is Fault

Check Point: Outdoor Power Board Is Fault

Count Measure: Change The Power Board

Code: E9

Fault: Power Board Is Fault

Check Point: Outdoor Power Board Is Fault

Count Measure: Change The Power Board

Code: E5

Fault: Driver Board Is Fault

Check Point: Driver Board Is Fault

Count Measure: Driver Board Is Fault

Code: EC

Fault: Oudoor Communication Faulty

Check Point: Check If Wirings Between Power Board And Driver Board Are Connected Well

Count Measure: Fix The Wiring Between Power Board And Driver Board

Code: E3

Fault: Indoor Motor Is Fault

Check Point:

- Indoor Motor Or Indoor Motor Capacitor Is Fault

- Inner Wiring Don’t Connect Well

- Indoor Pcb Is Fault

- Indoor Motor Is Blocked

Count Measure:

- Change Motor Or Capacitor

- Fix The Wirings

- Change Indoor Pcb

- Remove The Blocking

Code: EE

Fault: Indoor Pcb Baord Is Faulty

Check Point: Indoor Pcb Baord Is Faulty

Count Measure: Indoor Pcb Baord Is Faulty

Code: P1

Fault: Outdoor Discharge Temp Is Too High

Check Point:

- Check If The Outlet Is Blocked Or The Condensor Is Dirty

- Check The Outdoor Motor Work Normally

- Check If The Refrigerant Is Charged Too Much

Count Measure:

- Remove Obstacle Around Outdoor Unit Or Wash The Condenser

- Change Outdoor Motor Or Motor Capacitor

- Regulate The Quantity Of Refrigerant

Code: P7

Fault: Driver Board Protection

Check Point:

- Check If The Refrigerant Is Charged Too Much

- Check If The Compressor Is Blocked

- Ipm Mold Is Fault

Count Measure:

- Regulate The Quantity Of Refrigerant

- Change Compressor

- Change Ipm Mold

Code: P3

Fault: The Voltage Is Not Stable

Check Point: Check The Power Supply

Count Measure: Restart The Air Conditioner

Code: P2

Fault: Electric Current Is Too High

Check Point:

- Check If The Refrigerant Is Charged Too Much

- Check If The Voltage Is Too Low, Power Wringis Too Thin Or Too Long Or Contact Badly

- Check If The Outlet Is Blocked Or The Condensor Is Dirty

- Check The Outdoor Motor Work Normally

Count Measure:

- Regulate The Quantity Of Refrigerant

Updating Power Supply, Chang Power Wiring

Remove Obstacle Around Outdoor Unit Or Wash The Condenser

Change Outdoor Motor Or Motor Capacitor

Code: P4

Fault: OCR Triped

Check Point:

- Compressor Ocr Is Open Curcuit

- Check If The Ocr Temperature Is Too High And Ocr Triped

Count Measure:

- Change Ocr Or Compressor

- Turn Off The Air Conditioner, And Restart It 2 Hour Later

- If Air Conditioner Is On And Off Regularly, Check Outdoor Motor Or Motor Capacitor, The Outlet Is Blocked Or The Condensor Is Dirty

Code: P5

Fault: Indoor Pipe Temp. Is Too High When Heating

Check Point:

- Check Indoor Motor Work Normally

- Check Filter Net Or Evaperator Is Diety

Count Measure:

- Change Outdoor Motor Or Motor Capacitor

- Wash The Filete Net Or Evaperator

Code: P6

Fault: Outdoor Pipe Temp. Id Too High

Check Point:

- Check If The Refrigerant Is Charged Too Much

- Check If The Voltage Is Too Low, Power Wringis Too Thin Or Too Long Or Contact Badly

- Check If The Outlet Is Blocked Or The Condensor Is Dirty

Count Measure:

- Regulate The Quantity Of Refrigerant

- Updating Power Supply, Chang Power Wiring

- Remove Obstacle Around Outdoor Unit Or Wash The Condenser

Code: P0

Fault: Driver Board Is Fault

Check Point: Driver Board Is Fault

Count Measure: Change Driver Baord

KFR-50GWZ/BM、KFR-70GWZ/BM Models;

Code: E1

Fault: Indoor Air Sensor Is Faulty

Check Point:

- Check The Sensor Value

- Indoor Board Is Fault

Count Measure:

- Change Sendor

- Change Indoor Board

Code: E2

Fault: Indoor Pipe Sensor Is Faulty

Check Point:

- Check The Sensor Value

- Indoor Board Is Fault

Count Measure:

- Change Sendor

- Change Indoor Board

Code: E3

Fault: Indoor In-phase Motor Is Fault

Code: E4

Fault: Communication Fault Between Indoor Unit And Outdoor Unit

Check Point:

- Check If The Connecting Wiring Is Connect Well

- Test The Voltage Value Between L4 And S, If It ‘s Change Regularly,the Singal Transfering Between Indoor And Outdoor Unit Is Good, When It’s No Change If Value Is Below 14v, The Indoor Pcb Board Is Fault, Change It. If Value Is Over 14v,the Outdoor Pcb Is Faulty

- Check If There Is Led Flashing On The Outdoor Pcb If There Is No Flashing,check Voltage Value From Power Board To Pfc Board, Between Acl And Can On Pfc Board If It’s Not 220v, Change Power Board If It’s 220v,change Pfc Board

Count Measure:

- Fix The Wiring Again

- Change Relate Pcb Board

Code: E5

Fault: Driver Board Is Fault

Check Point: Driver Board Is Fault

Count Measure: Driver Board Is Fault

Code: E6

Fault: Outdoor Sensor Is Fault

Check Point:

- Check The Sendor Value

- Power Board Is Fault

Count Measure:

- Change Sensor

- Change Power Baord

Code: E7

Fault: Indoor Motor Faulty

Code: E8

Fault: Communication Signal Is Not Good

Check Point:

- Check If The Communication Wiring Is Connected Well.

- Check If Power Board Or Driver Board Is Fault

Count Measure:

- Fix The Communication Well

- Change The Pcb Board

Code: P0

Fault: Driver Board Is Fault

Check Point: Driver Board Is Fault

Count Measure: Driver Board Is Fault

Code: P1

Fault: OCR Triped

Check Point:

- Compressor Ocr Is Open Curcuit

- Check If The Ocr Temperature Is Too High And Ocr Triped

Count Measure:

- Change Ocr Or Compressor

- Turn Off The Air Conditioner, And Restart It 2 Hour Later

- If Air Conditioner Is On And Off Regularly, Check Outdoor Motor Or Motor Capacitor, The Outlet Is Blocked Or The Condensor Is Dirty

Code: P2

Fault: Power Board Is Fault

Check Point: Outdoor Power Board Is Fault

Count Measure: Change The Power Board

Code: P3

Fault: IPDU Is Fault

Code: P4

Fault: Indoor Unit Don’t Match Outdoor Unit

Check Point: Check If The Indoor Unit Match Outdoor Uint

Count Measure: Change Wrong Unit

Code: P5

Fault: Electric Current Is Too High

Check Point:

- Check If The Refrigerant Is Charged Too Much

- Check If The Voltage Is Too Low, Power Wringis Too Thin Or Too Long Or Contact Badly

- Check If The Outlet Is Blocked Or The Condensor Is Dirty

- Check The Outdoor Motor Work Normally

Count Measure:

- Regulate The Quantity Of Refrigerant

- Updating Power Supply, Chang Power Wiring

- Remove Obstacle Around Outdoor Unit Or Wash The Condendsor

- Change Outdoor Motor Or Motor Capacitor

Code: P6

Fault: The Voltage Is Not Stable

Check Point: Check The Power Supply

Count Measure: Restart The Air Conditioner

Code: P7

Fault: Pfc Faulty

Check Point: Outdoor Pfc Board Is Fault

Count Measure: Change Pfc Board

Code: P8

Fault: Indoor Motor Feedback Faulty

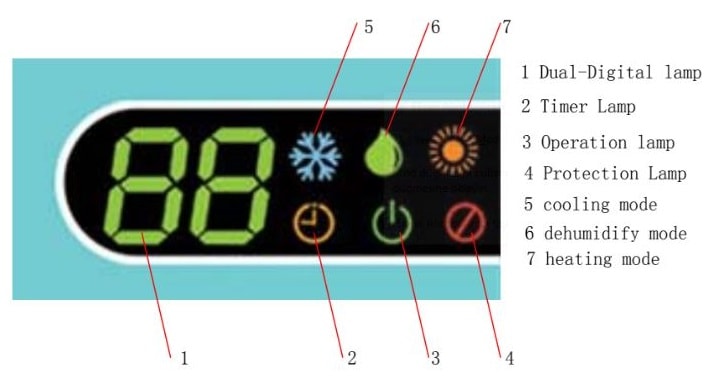

Note: The fault code doesn’t display directly, and it will display as following instruction:

Press the ON/OFF button 6 times within 7 seconds, there will be three DU sound on indoor unit, and the indoor unit will display the fault code.

Model:

KFR-25GWZ/BM, KFR-35GWZ/BM, KFR-50GWZ/BM, KFR-70GWZ/BM

Shinco Portable AC Error Codes:

- E2 Room temperature sensor error

- E3 Coil pipe sensor error

- FL Water full status

Caution: When “df” is displayed, the air conditioner is in anti-freezing or defrosting state, and this is a normal phenomenon.

Troubleshooting

Before calling a repair man, please check the followings:

Symptom: The air conditioner does not work

Possible reason:

- Problem with the remote control.

- Problem with the voltage. Please shut the power, wait 3 minutes and restart the unit.

- Verify the circuit breaker or fuse.

Symptom: The unit does not blow warm air in heating mode

Possible reason:

- The compressor is in a delay mode (to protect the compressor there are several minutes delay for every start) wait a few minutes after starting the unit.

- The hot air will be blown out only after the defrosting operation.

Symptom: Low efficiency of cooling or heating

Possible reason:

- The air filters are too dirty.

- The intake vent or outlet vent is blocked up.

- In heating operation, the ambient temperature is too low. Defrosting operation may be required.

Symptom: Noise

Possible reason:

- Water leak noise. It is the sound of the circulation of refrigerant.

- Condensed air leaking out. In heating operation, during the defrosting, it is the sound of the back-flow refrigerant.

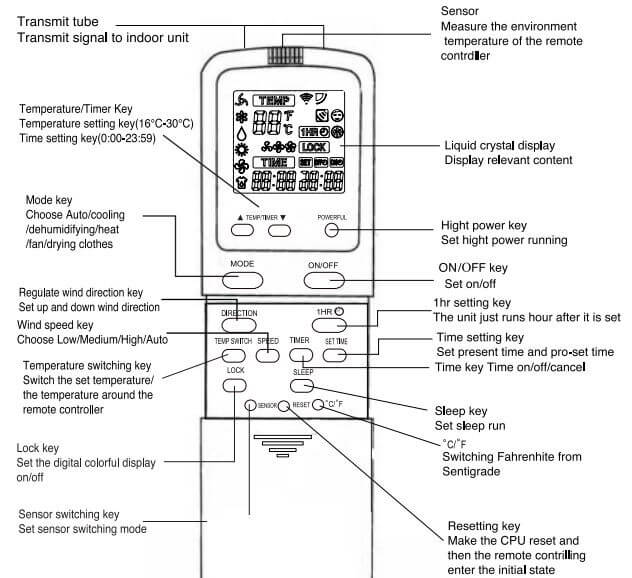

Symptom: Abnormality on the remote control screen

Possible reason:

- Batteries need to be replaced.

- Batteries are inserted incorrectly. Take the batteries out and insert them again.

Symptom: Cold water leaking from the air conditioner

Possible reason: Moisture will occur in the air outlet due to the temperature difference

Comments

Post a Comment