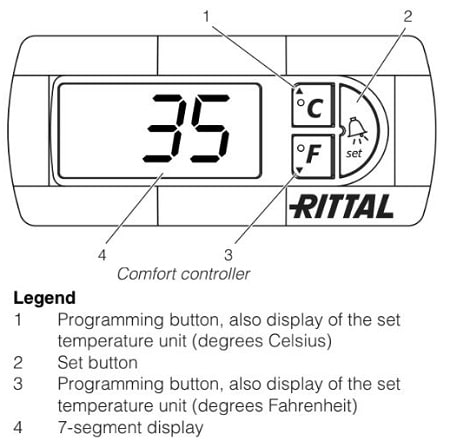

System messages are shown on the display screen of the Comfort controller via the displays A1 to A20 and E0.

Rittal AC Fault Indication and Fault Analysis:

Fault: 1

Cause: Cooling output too low (lack of coolant) Consequential fault or faults 2-7. Remedy: Check cooling output Carry out cooling service.

Fault: 2 Cause: Compressor overloaded (internal winding protection). Remedy: Unit will switch on automatically.

Fault: 3 Cause: Operational indication if risk of icing up exists. Remedy: Raise the setpoint value of the internal temperature of enclosure.

Fault: 4 Cause: Ambient temperature too high. Remedy: Unit’s specified range of application exceeded

Fault: 5 Cause: Blocked or defective. Remedy: Replace.

Fault: 6 Cause: Blocked or defective. Remedy: Replace.

Fault: 7

Cause: Filter mat contaminated. Remedy: Clean or replace.

Fault: 8 Cause: Cable break or short-circuit. Remedy: Replace.

Fault: 9 Cause: Incorrect field of rotation. Remedy: Reverse two phases.

Troubleshooting

Trouble: The unit does not switch on.

Possible Cause: No power supply.

Correction: Check the mains connection and the pre-fuse.

Trouble: The unit does not cool/heat adequately.

Possible Cause:

- The air circulation inside the enclosure is impaired.

- Ambient temperature too high/low.

- Filter equipment contaminated.

- Internal fan defective.

- External fan defective.

- The heat produced in the enclosure exceeds the cooling capacity of the Peltier climate control unit.

Correction:

- Check the air circulation inside the enclosure. Check, in particular, those components equipped with a fan. Check the free spaces above and below the main heat dissipation sources.

- Reduce the ambient temperature. Protect the unit from radiation heat caused by direct sunshine and hot surfaces.

- Check the filter and, if necessary, clean or replace.

- Replace unit.

- Replace unit.

- Reduce the heat loss.

Trouble: Condensation.

Possible Cause:

- Enclosure leakages.

- Internal temperature of enclosure set too low.

Correction:

- Check the enclosure for leaks (IP 54). Check, in particular, the cable entry points for leaks.

- Check the set enclosure internal temperature (factory setting: +35°C).

Comments

Post a Comment