Warning; Disconnect all power to unit before servicing. contactor may break only one side. Failure to shut off power can cause electrical shock resulting in personal injury or death.

Comfort Alert Diagnosis Chart Single Phase Unit

Status LED: Green “POWER”

Status LED Description: Module has power

Status LED Troubleshooting Information: Supply voltage is present at module terminals

Status LED: Red “TRIP”

Status LED Description: Thermostat demand signal Y1 is present, but the compressor is not running

Status LED Troubleshooting Information:

- Compressor internal overload is open

- Broken wire or connector is not making contact

- Low pressure switch open, if present

- Compressor contactor has failed open

Status LED: Yellow “ALERT” Flash Code 1

Status LED Description: Long Run Time Compressor is running extremely long run cycles

Status LED Troubleshooting Information:

- Low refrigerant charge

- Evaporator blower is not running

- Evaporator coil is frozen

- Faulty TXV

- Condenser coil is dirty

- Liquid line restriction (filter drier blocked if present in system)

- Thermostat is malfunctioning

Status LED: Yellow “ALERT” Flash Code 2

Status LED Description: System Pressure Trip Discharge or suction pressure out of limits or compressor overloaded

Status LED Troubleshooting Information:

- Condenser coil poor air circulation (dirty, blocked, damaged)

- Condenser fan is not running

- Return air duct has substantial leakage

- If low pressure switch is present, check flash code (1) information

Status LED: Yellow “ALERT” Flash Code 3

Status LED Description: Short Cycling Compressor is running only briefly

Status LED Troubleshooting Information:

- High head pressure

- Thermostat demand signal is intermittent

- Time delay relay defective, if present

- Hot gas sensor defective, if present

Status LED: Yellow “ALERT” Flash Code 4

Status LED Description: Locked Rotor

Status LED Troubleshooting Information:

- Run capacitor has failed

- Low line voltage (contact utility if voltage at disconnect is low)

- Excessive liquid refrigerant in compressor

- Compressor bearings are seized

Status LED: Yellow “ALERT” Flash Code 5

Status LED Description: Open Circuit

Status LED Troubleshooting Information:

- Compressor contactor has failed open

- High pressure switch is open, If present

- Open circuit in compressor supply wiring or connections

- Unusually long compressor protector reset time due to extreme ambient temperature

- Compressor windings are damaged

Status LED: Yellow “ALERT” Flash Code 6

Status LED Description: Open Start Circuit Current only in run circuit

Status LED Troubleshooting Information:

- Run capacitor has failed

- Open circuit in compressor start wiring or connections

- Compressor start winding is damaged

Status LED: Yellow “ALERT” Flash Code 7

Status LED Description: Open Run Circuit Current only in start circuit

Status LED Troubleshooting Information:

- Open circuit in compressor run wiring or connections

- Compressor run winding is damaged

Status LED: Yellow “ALERT” Flash Code 8

Status LED Description: Welded Contactor Compressor always runs

Status LED Troubleshooting Information:

- Compressor contactor has failed closed

- Thermostat demand signal not connected to module

Status LED: Yellow “ALERT” Flash Code 9

Status LED Description: Low Voltage Control circuit < 17VAC

Status LED Troubleshooting Information:

- Control circuit transformer is overloaded

- Low line voltage (contact utility if voltage at disconnect is low)

Ruud Air Conditioner Troubleshooting

Symptom: Unit will not run

Possible Cause:

- Power off or loose electrical connection

- Thermostat out of calibration-set too high

- Defective contactor

- Blown fuses

- Transformer defective

- High pressure control open (if provided)

- Interconnecting low voltage wiring damaged

Remedy:

- Check for correct voltage at compressor contactor in control box

- Reset

- Check for 24 volts at contactor coil – replace if contacts are open

- Replace fuses

- Check wiring-replace transformer

- Reset-also see high head pressure remedy-The high pressure control opens at 610 PSIG

- Replace thermostat wiring

Symptom: Condenser fan runs, compressor doesn’t

Possible Cause:

- Run or start capacitor defective (single phase only)

- Start relay defective (single phase only)

- Loose connection

- Compressor stuck, grounded or open motor winding. open internal overload

- Low voltage condition

- Low voltage condition

Remedy:

- Replace

- Replace

- Check for correct voltage at compressor – check & tighten all connections

- Wait at least 2 hours for overload to reset. If still open, replace the compressor.

- At compressor terminals, voltage must be within 10% of rating plate volts when unit is operating.

- Add start kit components.

Symptom: Insufficient cooling

Possible Cause:

- Improperly sized unit

- Improper airflow

- Incorrect refrigerant charge

- Air, non-condensibles or moisture in system

- Incorrect voltage

Remedy:

- Recalculate load

- Check – should be approximately 400 CFM per ton.

- Charge per procedure attached to unit service panel

- Recover refrigerant, evacuate & recharge, add filter drier

- At compressor terminals, voltage must be within 10% of rating plate volts when unit is operating.

Symptom: Compressor short cycles

Possible Cause:

- Incorrect voltage

- Defective overload protector

- Refrigerant undercharge

Remedy:

- At compressor terminals, voltage must be ± 10% of nameplate marking when unit is operating.

- Replace – check for correct voltage

- Add refrigerant

Symptom: Registers sweat

Possible Cause: Low evaporator airflow

Remedy: Increase speed of blower or reduce restriction – replace air filter

Symptom: High head-low vapor pressures

Possible Cause:

- Restriction in liquid line, expansion device or filter drier

- Flow check piston size too small

- Incorrect capillary tubes

- TXV does not open

Remedy:

- Remove or replace defective component

- Change to correct size piston

- Change coil assembly

- Replace TXV

Symptom: High head-high or normal vapor pressure – Cooling mode

Possible Cause:

- Dirty condenser coil

- Refrigerant overcharge

- Condenser fan not running

- Air or non-condensibles in system

Remedy:

- Clean coil

- Correct system charge

- Repair or replace

- Recover refrigerant, evacuate & recharge

Symptom: Low head-high vapor pressures

Possible Cause:

- Flow check piston size too large

- Defective Compressor valves

- Incorrect capillary tubes

Remedy:

- Change to correct size piston

- Replace compressor

- Replace coil assembly

Symptom: Low vapor – cool compressor – iced evaporator coil

Possible Cause:

- Low evaporator airflow

- Operating below 65°F outdoors

- Moisture in system

- TXV limiting refrigerant flow

Remedy:

- Increase speed of blower or reduce restriction – replace air filter

- Add Low Ambient Kit

- Recover refrigerant – evacuate & recharge – add filter drier

- Replace TXV

Symptom: High vapor pressure

Possible Cause:

- Excessive load

- Defective compressor

Remedy:

- Recheck load calculation

- Replace

Symptom: Fluctuating head & vapor pressures

Possible Cause:

- TXV hunting

- Air or non-condensibles in system

Remedy:

- Check TXV bulb clamp – check air distribution on coil – replace TXV

- Recover refrigerant, evacuate & recharge

Symptom: Gurgle or pulsing noise at expansion device or liquid line

Possible Cause: Air or non-condensibles in system

Remedy: Recover refrigerant, evacuate & recharge

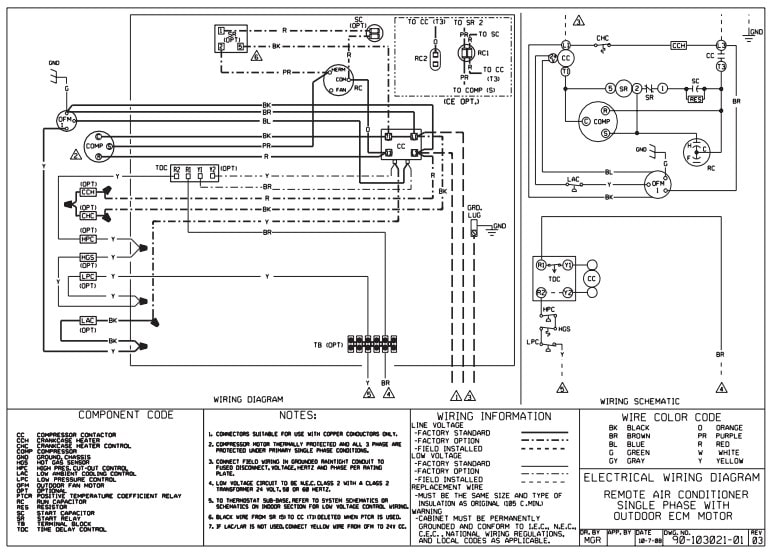

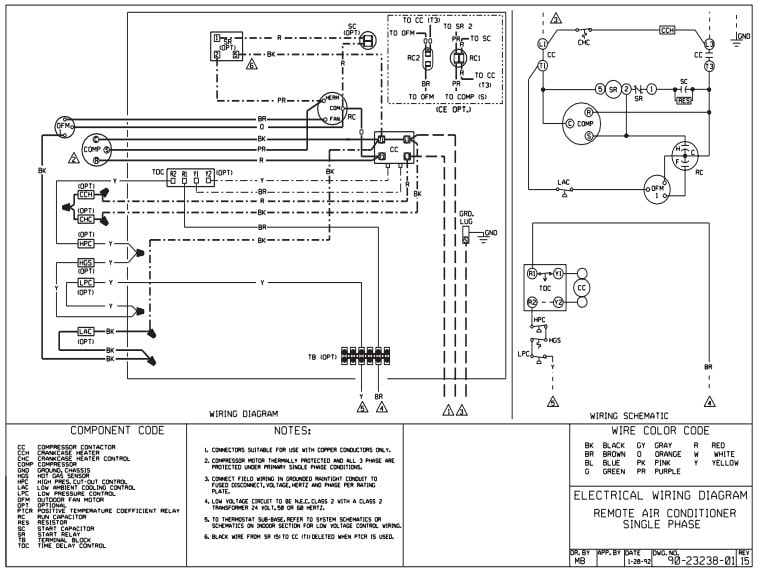

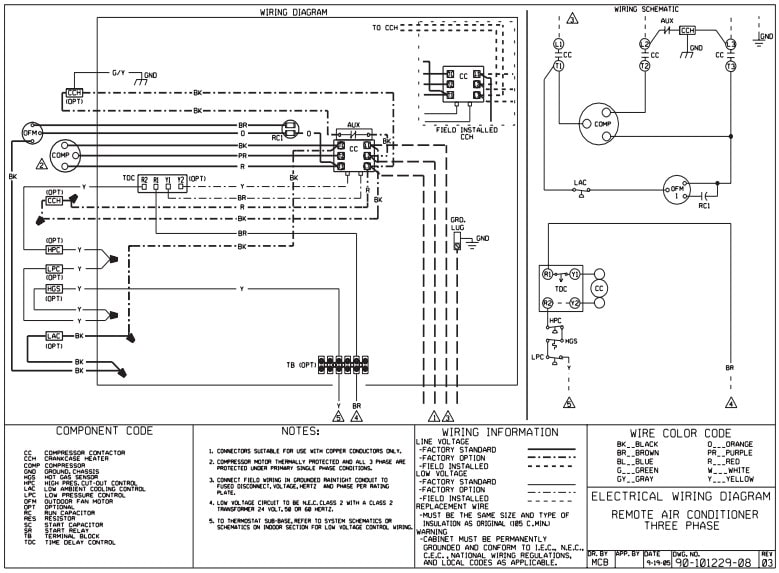

Wiring Diagram

Ruud Air Conditioners Manual PDF

Comments

Post a Comment