When the controller displays malfunction,please turn off the unit to stop the malfunction display,ask for the professional to debug.

The meaning of error codes as shown in below:

| Error Codes | Meaning |

|---|---|

| E1 | High pressure protection of compressor |

| E2 | Indoor anti-frozen protection |

| E3 | Low pressure protection of compressor |

| E4 | Discharge temp. protection of compressor |

| E5 | Compressor overload protection |

| E6 | Transmit malfunction |

| E7 | Modes conflict |

| F0 | Indoor environment temp. sensor mal-function |

| F1 | Indoor pan tube inlet tube temp. sensor malfunction |

| F2 | Indoor pan tube middle temp. sensor malfunction |

| F3 | Indoor pane tube outlet tube temp. sensor malfunction |

| F4 | Outdoor environment temp. sensor malfunction |

| F5 | Outdoor pan tube inlet tube temp. sensor malfunction |

| F6 | Outdoor pan tube middle temp. sensor malfunction |

| F7 | Outdoor pan tube outlet tube temp. sensor malfunction |

| F8 | Discharge temp. sensor 1 (rated frequency) malfunction |

| F9 | Discharge temp. sensor 2 (digital) malfunction |

| FA | Greasy temp. temp. sensor 1 (rated frequency) malfunction |

| Fb | Greasy temp. temp. sensor 2 (digital) malfunction |

| FC | High pressure sensor malfunction |

| Fd | Low pressure sensor malfunction |

Troubleshooting

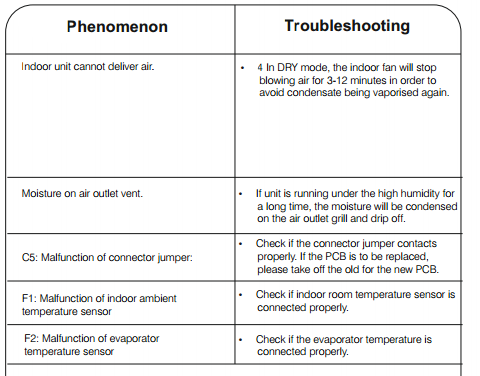

Phenomenon: C5 Malfunction of connector jumper

Troubleshooting: Check if the connector jumper contacts properly. If the PCB is to be replaced, please take off the old for the new PCB.

Phenomenon: F1 Malfunction of indoor ambient temperature sensor

Troubleshooting: Check if indoor room temperature sensor is connected properly.

Phenomenon: F2 Malfunction of evaporator temperature sensor

Troubleshooting: Check if the evaporator temperature is connected properly.

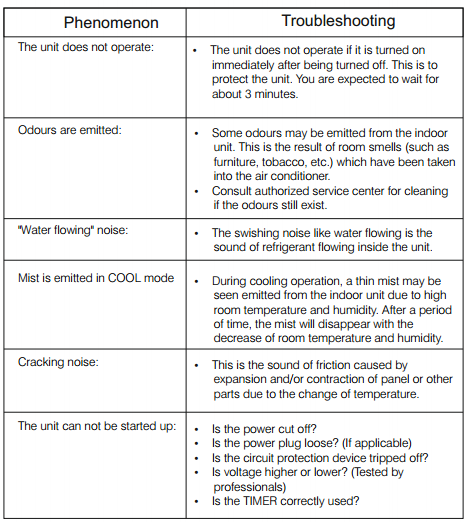

Phenomenon: The unit does not operate

Troubleshooting: The unit does not operate if it is turned on immediately after being turned off. This is to protect the unit. You are expected to wait for about 3 minutes.

Phenomenon: Odours are emitted

Troubleshooting:

- Some odours may be emitted from the indoor unit. This is the result of room smells (such as furniture, tobacco, etc.) which have been taken into the air conditioner.

- Consult authorized service center for cleaning if the odours still exist.

Phenomenon: “Water flowing” noise

Troubleshooting: The swishing noise like water flowing is the sound of refrigerant flowing inside the unit.

Phenomenon: Mist is emitted in COOL mode

Troubleshooting: During cooling operation, a thin mist may be seen emitted from the indoor unit due to high room temperature and humidity. After a period of time, the mist will disappear with the decrease of room temperature and humidity.

Phenomenon: Cracking noise

Troubleshooting: This is the sound of friction caused by expansion and/or contraction of panel or other parts due to the change of temperature.

Phenomenon: The unit can not be started up

Troubleshooting:

- Is the power cut off?

- Is the power plug loose? (If applicable)

- Is the circuit protection device tripped off?

- Is voltage higher or lower? (Tested by professionals)

- Is the TIMER correctly used?

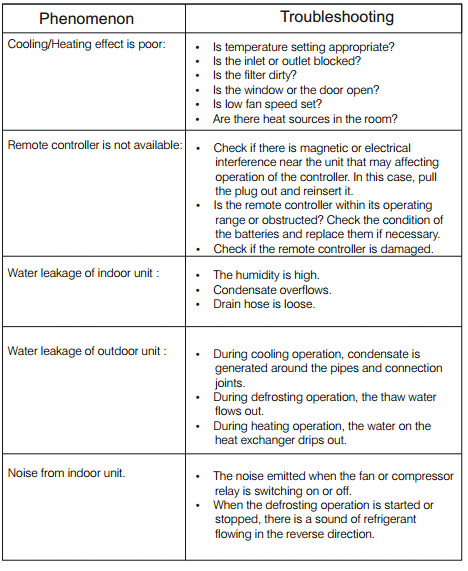

Phenomenon: Cooling/Heating effect is poor

Troubleshooting:

- Is temperature setting appropriate?

- Is the inlet or outlet blocked?

- Is the filter dirty?

- Is the window or the door open?

- Is low fan speed set?

- Are there heat sources in the room?

Phenomenon: Remote controller is not available

Troubleshooting:

- Check if there is magnetic or electrical interference near the unit that may affecting operation of the controller. In this case, pull the plug out and reinsert it.

- Is the remote controller within its operating range or obstructed? Check the condition of the batteries and replace them if necessary.

- Check if the remote controller is damaged.

Phenomenon: Water leakage of indoor unit

Troubleshooting:

- The humidity is high.

- Condensate overflows.

- Drain hose is loose.

Phenomenon: Water leakage of outdoor unit

Troubleshooting:

- During cooling operation, condensate is generated around the pipes and connection joints.

- During defrosting operation, the thaw water flows out.

- During heating operation, the water on the heat exchanger drips out.

Phenomenon: Noise from indoor unit

Troubleshooting:

- The noise emitted when the fan or compressor relay is switching on or off.

- When the defrosting operation is started or stopped, there is a sound of refrigerant flowing in the reverse direction.

Phenomenon: Indoor unit cannot deliver air

Troubleshooting: 4 In DRY mode, the indoor fan will stop blowing air for 3-12 minutes in order to avoid condensate being vaporised again.

Phenomenon: Moisture on air outlet vent

Troubleshooting: If unit is running under the high humidity for a long time, the moisture will be condensed on the air outlet grill and drip off.

Model: INV18SLU-C8/INV18SLU-R8/INV18SLU-S8

Comments

Post a Comment